How To Get A Quote

***Online pricing not available, Please request a quote:***

How To Get A Quote:

Option 1:

Contact Us to make sure you are getting the best unit possible. These machines are complex so let us help you get exactly what you need!

Option 2: (quickest response times)

Step 1. Add the item to your cart

Step 2. Checkout or Click on the Chat button box that is at the bottom right of your screen

Step 3. Please tell us any info you think we would need to know

Step 4. Relax, our team is processing your request and an expert will be in touch to get you exactly what you need!

Product Description

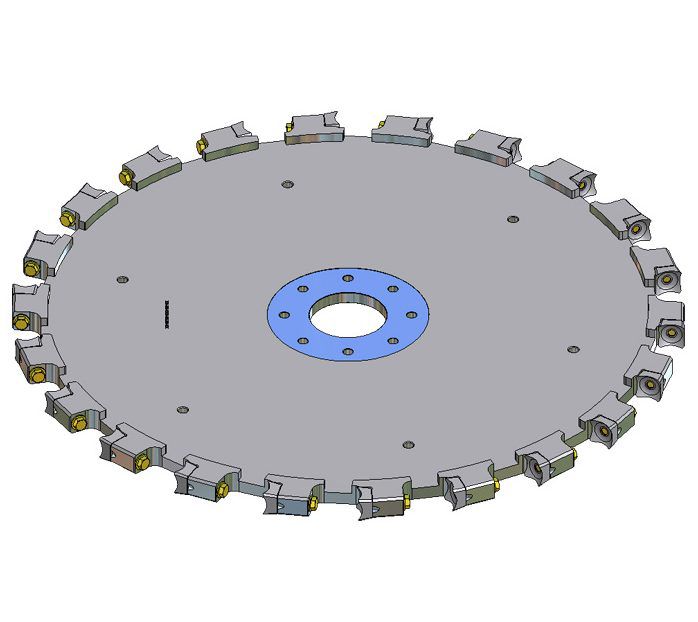

Gilbert Cutting Tools Saw Blades & Teeth | Hi-Cut II Series & 1200H Series | Machine Size 20-30 Tons For Excavators

DESCRIPTION

Gilbert’s range of blades and saw teeth are indeed designed to cater to various forestry tasks, ensuring high cutting quality and efficiency.

The Gilbert Cutting Tools Saw Blades & Teeth are engineered for superior performance in forestry applications. Available in the Hi-Cut II Series and 1200H Series, these blades are designed to handle the tough demands of cutting through both hardwood and softwood, ensuring clean and precise cuts. The Hi-Cut II Series features a one-piece machined blade that offers exceptional cutting performance and fuel efficiency. The 1200H Series is the go-to choice for a wide range of cutting jobs, known for its durability and popularity as a replacement blade. In addition, Gilbert's saw teeth, such as the Hi-Cut Tooth and Concave Tooth, provide excellent cutting quality and superior impact resistance, making them a reliable and cost-effective solution for forestry tasks. These cutting tools are designed to work seamlessly with excavators, providing unmatched cutting power, efficiency, and longevity.

Here are some key points about Gilbert saw blades:

- Wide Range: Offers a variety of blades and saw teeth for different forestry jobs.

- Cutting Quality: Known for unmatched cutting quality, ensuring clean and precise cuts.

- Adaptability: Well-suited to the speed of the carriers, which helps in preventing damage to the fiber.

- Performance: Delivers high performance and productivity, making them a reliable choice for forestry operations.

Key Features

- Heavy‑Duty Compatibility – Engineered for 20–30 t excavator‑mounted harvesters and feller bunchers

- Hi‑Cut II Series Blades – One‑piece machined design with 22 teeth for smoother cuts and superior resistance to bending/twisting

- 1200H Series Blades – Versatile cutting tool range with welded tooth supports for extended service life and excellent value

- Material Versatility – Both series perform exceptionally in hardwood and softwood applications

- Optimized Cutting Performance – Hi‑Cut teeth deliver sharp, precise, and durable results; concave teeth offer high lateral clearance and cost‑efficient cutting

- Fuel & Energy Efficiency – Blade and tooth designs reduce cutting resistance, lowering fuel consumption

- Multiple Tooth Options – Hi‑Cut teeth available in 2 in and 2.25 in sizes; concave teeth in standard sizes for most applications

- Proven Forestry Use – Popular choices for logging, land clearing, and high‑production timber harvesting

- Hi-Cut II Series Blades: One-piece machined design for superior cutting.

- 1200H Series Blades: Ideal for various forestry jobs, equipped with welded tooth supports.

- Hi-Cut Tooth: Features a tapered cutting face for improved impact resistance.

- Concave Tooth: High lateral clearance for efficient cutting and reduced operating costs.

- Durable Construction: Thick, resistant blades for extended service life and minimal maintenance.

Detailed Specifications

Hi‑Cut II Series Saw Blade

| Specification | Details |

|---|---|

| Design | One‑piece machined blade |

| Material | Suitable for hardwood & softwood |

| Teeth | 22 teeth for smoother cut |

| Clearance | Optimum clearance from tree plate |

| Performance | High cutting quality |

| Durability | Superior resistance to bending/twisting |

| Efficiency | Significant fuel & energy savings |

| Popular Use | Forestry applications |

| Machine Size Compatibility | Typically for 20–30 t forestry harvesters/feller bunchers |

1200H Series Saw Blade

| Specification | Details |

|---|---|

| Design | Variety of cutting tools |

| Material | Excellent for both hardwood & softwood |

| Teeth | Hi‑Cut teeth |

| Clearance | Welded tooth supports |

| Performance | Popular for its performance |

| Durability | Increased service life due to construction |

| Efficiency | Offers excellent value for money |

| Popular Use | Most popular replacement blade |

| Machine Size Compatibility | Typically for 20–30 t forestry harvesters/feller bunchers |

Hi‑Cut Tooth

| Specification | Details |

|---|---|

| Design | Tapered cutting face |

| Cutting Quality | Sharp, precise, and durable |

| Stability | Flat back for solid seat |

| Sizes Available | 2 in. and 2.25 in. |

| Popularity | Most popular saw tooth |

| Machine Size Compatibility | Fits saw blades used on 20–30 t forestry carriers |

Concave Tooth

| Specification | Details |

|---|---|

| Design | High lateral clearances |

| Cutting Quality | Excellent cutting performance |

| Stability | Cost‑efficient design |

| Sizes Available | Standard size for most applications |

| Popularity | Competitive pricing |

| Machine Size Compatibility | Fits saw blades used on 20–30 t forestry carriers |

Manuals & Documents

General Warranty Info:

- Ripping It Outdoors works closely with our manufacturers to supply and support your products warranty needs as best as possible!

- The majority of products come with a manufacturer represented warranty against manufacturing defects for at least a 12 month period after the date of sale.

- Expendable components and "wear parts" including but not limited to blades, knives, teeth, oil, chain sprockets, skid shoes, knife mounting discs, and similar components are usually excluded from manufacturer warranties.

- Please reach out to us for any specific warranty information needed about products and parts you can’t find!

Videos

Shipping

$1 Shipping Quote Info:

- Contact Us For Shipping Quotes. All $1 products are listed as quote only because we can not display their pricing online.

- Low shipping rates for customers. We have negotiated the best possible rates for customers from our trusted carriers (ODFL, ESTES, UPS, and FedEx) & Top Private Drivers

- Negotiate shipping rates if you think we can do better please reach out. Keep in mind some shipping rates also include assembly & configuration as well!

- Complimentary lift gate service on all freight shipments where it’s possible. We guarantee safe delivery!