Product Description

GÖWEIL | VARIO-MASTER | Baler-Wrapper Combination | Working width 11.48 feet | 80-140 cm Bale Diameter | Minimum 90 kW (120 HP) | For Tractor

DESCRIPTION

Introducing the GÖWEIL VARIO-MASTER V140, a state-of-the-art baler-wrapper combination designed to efficiently process and package a wide range of materials, including agricultural waste, RDF, plastics, wood, and more. This innovative machine is engineered to provide high compression strength, compacting materials to a minimal volume, and ensuring optimal storage and transportation.

The VARIO-MASTER V140 features a hydraulically powered variable bale chamber, allowing for bale diameters from 2.7 to 4.6 feet, adjustable in 5 cm steps. The machine is equipped with a dual binding unit for net and film, ensuring secure and efficient wrapping of the bales. The PROFI plus L terminal provides intuitive control over the machine, allowing for easy operation and monitoring of the workflow.

With its advanced technology and robust design, the VARIO-MASTER V140 is the perfect solution for agricultural and industrial enterprises looking to optimize their material handling and packaging processes. Whether you're processing corn silage, CCM, alfalfa, hemp, or other materials, this machine is designed to deliver high-quality results and minimize waste.

Key Features

- Hydraulically Powered Variable Bale Chamber: Produces bale diameters from 2.7 to 4.6 feet with four adjustable speed levels.

- Versatile Multicrop Feeder: Equipped with a dosing drum for optimal processing of diverse materials.

- Intuitive PROFI plus L Handset: Provides easy and comprehensive control of all machine functions.

- High Compression: Compacts materials to a minimal volume for efficient storage.

- Standard Brake System: Fitted with a dual-line air brake or hydraulic dual-line brake system for safe operation.

- Automatic Central Lubrication: Ensures continuous lubrication of key points for extended service life.

- Intelligent "PROFI" Program Control: Fully automates the baling and wrapping process.

- Integrated LED Work Lights: Provides excellent illumination for nighttime operation.

- Agile Pivoting Drawbar: Swivels up to 30° for tight turns and flexible connection.

- Rapid Machine Setup: Ready for operation in approximately three minutes.

- Large Film Storage: Holds up to 18 rolls of film for extended work cycles.

- Optional High-Speed Chassis: 80 km/h capability for quick transport (with specific brake system).

- Combined Dual Binding Unit: Standard for both net and film binding.

- Refeed Belt: Prevents material loss and keeps the feeding process clean.

- Mobile Wrapping Table: Slides under the bale chamber for fast and gentle bale transfer.

- Twin Wrapping Arm: Ensures efficient and rapid wrapping.

- Film Monitoring and Single-Film Mode: Minimizes wrapping interruptions.

-

Hydraulically Lowerable Bale Delivery Ramp: Ensures gentle bale deposit.

Detailed Specifications

| Category | Specification |

|---|---|

| Machine Type | Baler-Wrapper Combination |

| Bale Chamber | Hydraulically powered, variable diameter |

| Bale Diameter Range | 2.7 to 4.6 feet (adjustable in 5 cm steps) |

| Binding System | Dual binding unit for net and film |

| Wrapper System | Twin wrapping arm with 2 × 750 mm film pre-stretchers |

| Feeder Type | Large-capacity Multicrop feeder with dosing drum |

| Feeder Volume | Approx. 459.09 ft³ (13 m³) |

| Scraper Floor | Galvanized, self-regulating Rübig scraper floor chains |

| Refeed Belt | Full-length, prevents material loss |

| Film Storage | Hydraulic, holds up to 18 rolls |

| Control System | PROFI plus L terminal with program control |

| Remote Operation | Hand-held transmitter for bale deposit |

| Lighting | LED work lights |

| Braking System | Dual-line air brake or hydraulic dual-line brake |

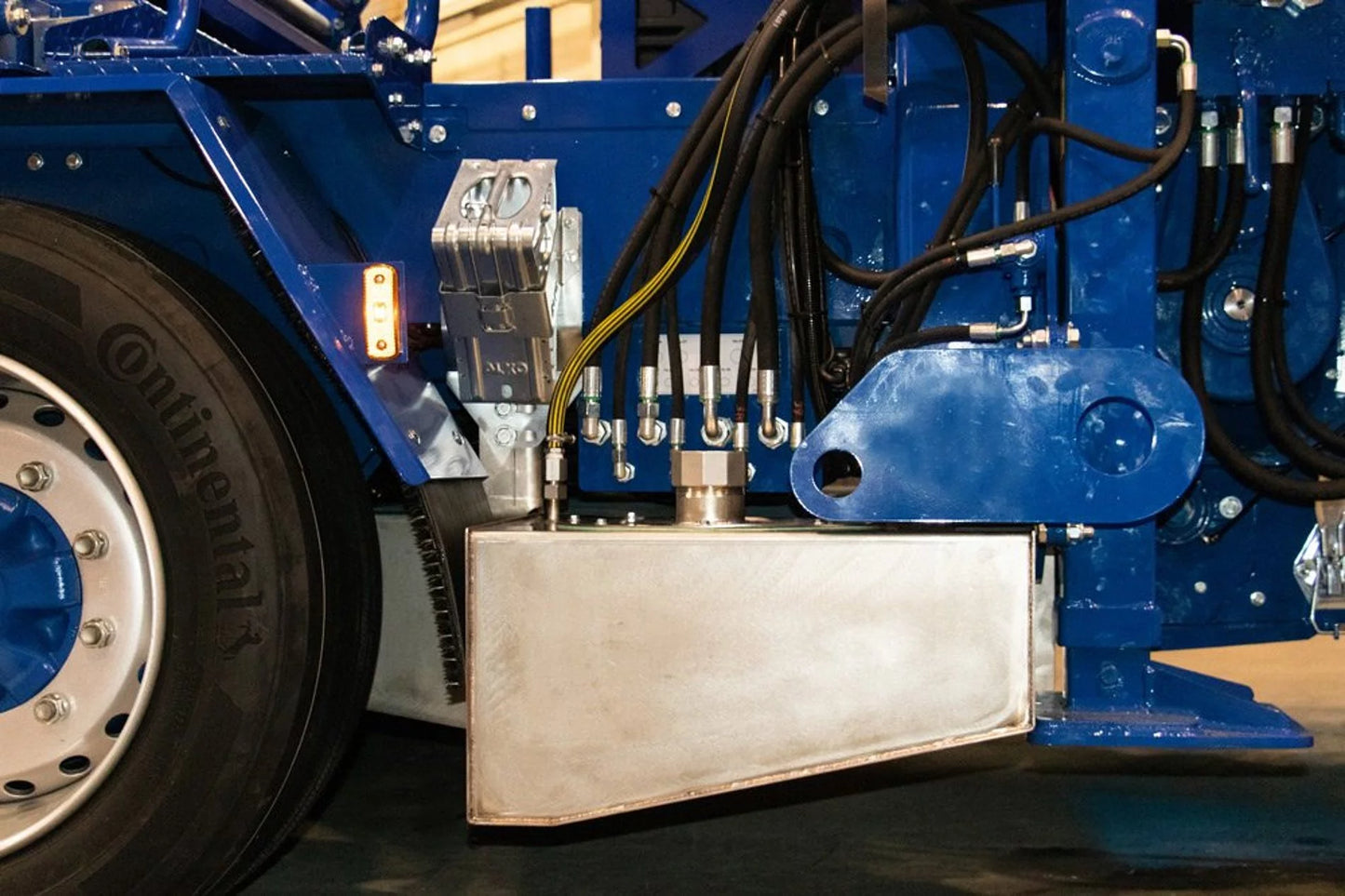

| Lubrication System | Fully automatic central lubrication for oil and grease |

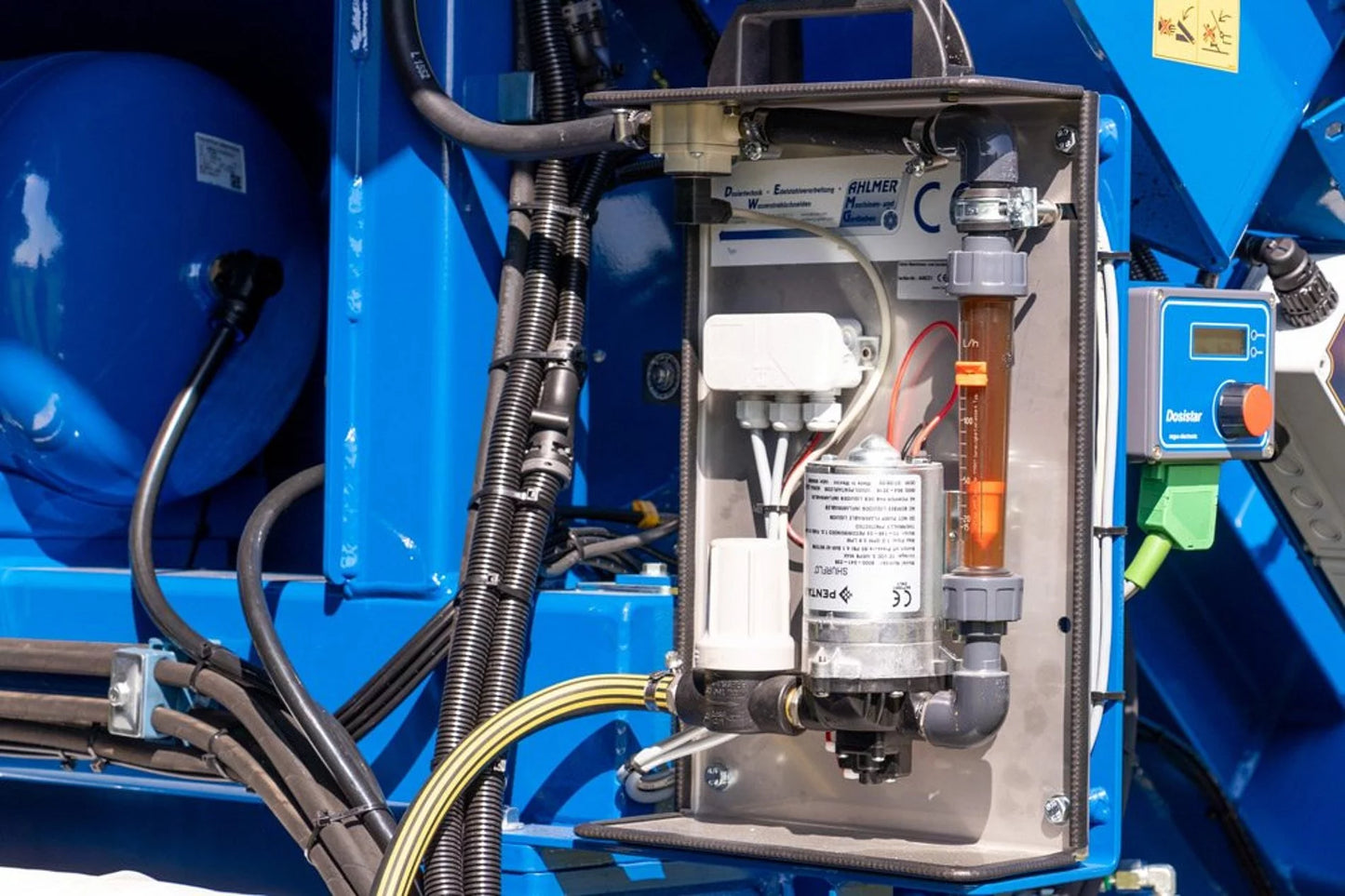

| Water Injection | Optional unit with solenoid valve and adjustable nozzles |

| Chassis | Tandem axle with suspension and 385/55 R22.5 tires |

| Drawbar | Height-adjustable, 30° pivot on either side |

| Camera System | 4 infrared cameras (bale chamber, elevator, wrapping table, rear) |

| Binding Materials | Compatible with net, film, or both simultaneously |

| Setup Time | Ready to use in ~3 minutes |

| Material Compatibility | RDF, plastics, wood chips, compost, carpet shreds, manure, miscanthus, sugar beet pulp, etc. |

| Compression Rate | 30% – 70% depending on material |

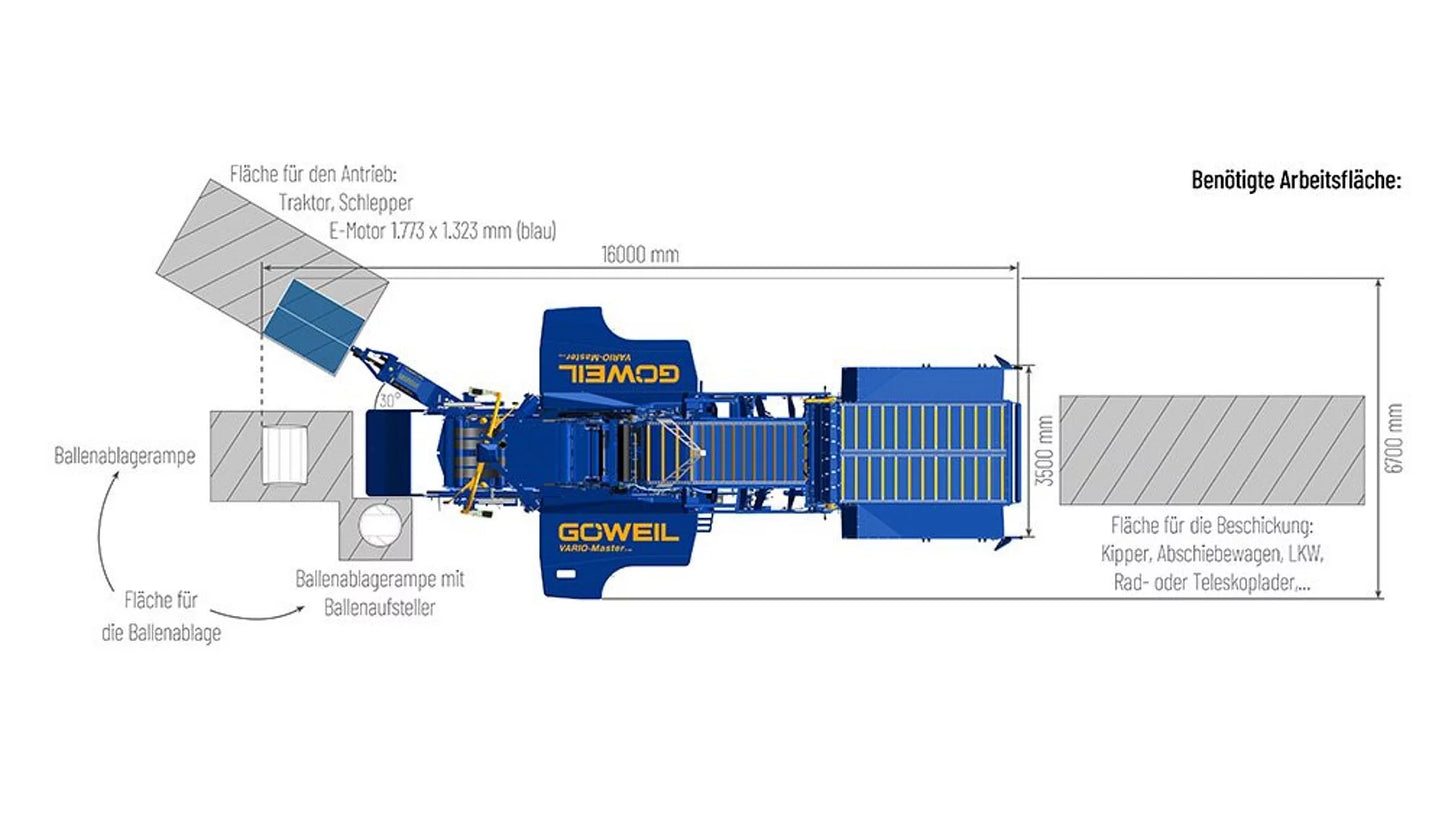

| Transport Dimensions | L: 38.6 feet × W: 8.4 feet × H: 13 feet |

| Work Dimensions | L: 46.5 feet × W: up to 20 feet × H: up to 14.4 feet |

| Machine Weight | 15,800 kg |

| Oil Requirement (Drawbar) | 10 L at 200 bar (2.5 gal at 200 bar) |

| Working Width (Feeder) | 11.48 feet (3.50 m) |

Manuals & Documents

Product Brochure

General Warranty Info:

- Ripping It Outdoors works closely with our manufacturers to supply and support your products warranty needs as best as possible!

- The majority of products come with a manufacturer represented warranty against manufacturing defects for at least a 12 month period after the date of sale.

- Expendable components and "wear parts" including but not limited to blades, knives, teeth, oil, chain sprockets, skid shoes, knife mounting discs, and similar components are usually excluded from manufacturer warranties.

- Please reach out to us for any specific warranty information neededabout products and parts you can’t find!

Videos

Shipping

General Shipping Info:

- Instantly calculate shipping quotes to the lower 48 states by 1. adding this product to your cart, 2. click continue to the checkout page and 3. enter your shipping address to check rates. Contact us for quotes for shipping to Hawaii, Alaska, Canada, Mexico and Internationally.

- Complimentary lift gate service on all freight shipments where it’s possible. We guarantee safe delivery!

- Low shipping rates for customers. We have negotiated the best possible rates for customers from our trusted carriers (ODFL, ESTES, UPS, and FedEx).

- Negotiate shipping rates if you think we can do better please reach out. Keep in mind some shipping rates also include assembly & configuration as well!