Product Description

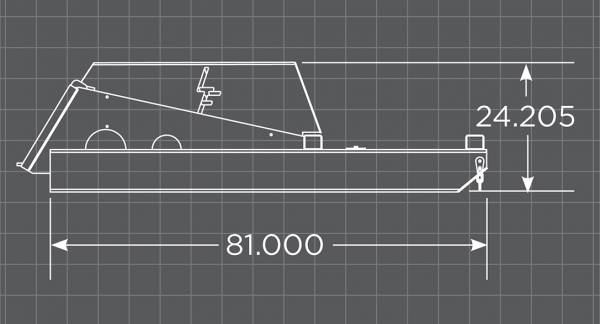

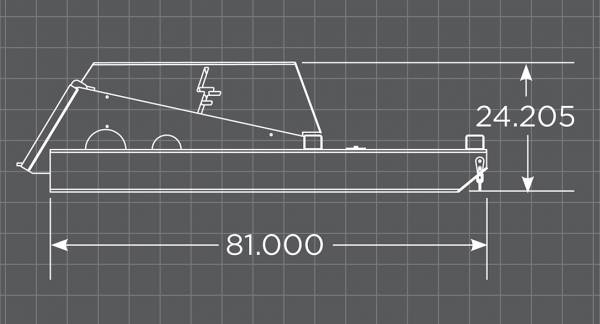

Loflin Fabrication | Closed Front Brush Cutter | 60" Width | 2 Blade | Hydraulic Flow 12 To 43 GPM | For Skid Steer

DESCRIPTION

Introducing the Loflin Fabrication LF Closed Front Brush Cutter, a heavy-duty and reliable attachment designed to tackle tough brush cutting tasks with ease. This closed front brush cutter is engineered for optimal performance, featuring a proprietary drive and a 1 piece heat treated forged steel axle for added strength and durability.

The housing is a 1 piece iron casting, providing a solid foundation for the cutter's operation. Two oversized tapered roller bearings are grease packed to prevent oil leaks, and the lower grease seal is wire protected for added protection. The direct drive system eliminates the need for gears or shear pins, ensuring a smooth and efficient cutting experience.

The Geroller style hydraulic motor is available in varying displacements to optimize cutting tip speed, and the hydraulic pressure relief system operates in both directions of rotation. The unit is bi-directional, allowing for easy operation and maneuverability.

The one piece forged steel fully heat treated bi-directional blades are designed for optimal cutting performance, and use common rotary cutter blade bolts and nuts for easy maintenance. The Parker brand hoses, fittings, and couplers come equipped with the unit, making it job site ready.

The motor/drive assembly is fully enclosed for protection, and the 1/4” thick reinforced steel deck provides added strength and durability. The LF Closed Front Brush Cutter is offered in size: 60”, and features a reinforced quick attach for easy attachment and detachment.

Units are available for both low and high flow machines, making this brush cutter a versatile and reliable choice for a variety of applications.

Key Features

- Proprietary Direct Drive System Eliminates shear pins and gears for reduced downtime.

- Bi-Directional Operation Reversible blade and hydraulic motor operation for improved efficiency and blade longevity.

- 1-Piece Forged Steel Axle Heat-treated for maximum strength and reliability.

- One-Piece Iron Cast Housing Provides unmatched durability and protection for internal components.

- Oversized Tapered Roller Bearings Grease-packed to eliminate oil leaks and reduce maintenance.

- Hydraulic Pressure Relief Built-in protection in both directions of motor rotation.

- Fully Enclosed Motor/Drive Assembly Protects against debris and external damage.

- Reinforced 1/4" Steel Deck Heavy-duty construction withstands the toughest conditions.

- Heat-Treated Forged Steel Blades Bi-directional design with standard rotary cutter hardware.

- Jobsite Ready Equipped with high-performance Parker hoses, fittings, and couplers.

- Available for Low & High Flow Machines Choose the hydraulic motor that fits your machine (12–43 GPM flow range).

-

Cutting Width Options Available in 60" models to match your workload.

Detailed Specifications

| Specification | Details |

|---|---|

| Brand | Loflin Fabrication |

| Model Name | LF Closed Front Brush Cutter |

| Cutting Width Available | 60" |

| Drive System | Proprietary Direct Drive (No gears/shear pins) |

| Axle | 1-Piece Heat-Treated Forged Steel |

| Housing | 1-Piece Cast Iron |

| Bearings | Oversized Tapered Roller (Grease-Packed) |

| Grease Seal | Lower Seal with Wire Protection |

| Hydraulic Motor | Geroller Style (Bi-Directional) |

| Blade Style | Forged Steel, Heat Treated, Bi-Directional |

| Blade Attachment | Uses Common Rotary Cutter Bolts & Nuts |

| Deck Thickness | 1/4" Reinforced Steel |

| Quick Attach | Reinforced Skid Steer Mount |

| Hydraulic Flow Options | 12–17 GPM (80cc), 15–22 GPM (100cc), 21–28 GPM (125cc), 28–34 GPM (160cc), 35–43 GPM (200cc) |

| Hose/Fittings | Parker Brand – Jobsite Ready |

| Compatibility | Universal Skid Steer Mount (Low/High Flow) |

Manuals & Documents

Product Catalogs

General Warranty Info:

- Ripping It Outdoors works closely with our manufacturers to supply and support your products warranty needs as best as possible!

- The majority of products come with a manufacturer represented warranty against manufacturing defects for at least a 12 month period after the date of sale.

- Expendable components and "wear parts" including but not limited to blades, knives, teeth, oil, chain sprockets, skid shoes, knife mounting discs, and similar components are usually excluded from manufacturer warranties.

- Please reach out to us for any specific warranty information neededabout products and parts you can’t find!

Videos

Shipping

General Shipping Info:

- Instantly calculate shipping quotes to the lower 48 states by 1. adding this product to your cart, 2. click continue to the checkout page and 3. enter your shipping address to check rates. Contact us for quotes for shipping to Hawaii, Alaska, Canada, Mexico and Internationally.

- Complimentary lift gate service on all freight shipments where it’s possible. We guarantee safe delivery!

- Low shipping rates for customers. We have negotiated the best possible rates for customers from our trusted carriers (ODFL, ESTES, UPS, and FedEx).

- Negotiate shipping rates if you think we can do better please reach out. Keep in mind some shipping rates also include assembly & configuration as well!