How To Request A Quote

***Online pricing not available, Please request a quote:***

How To Get A Quote:

Option 1:

Contact Us to make sure you are getting the best unit possible. These machines are complex so let us help you get exactly what you need!

Option 2: (quickest response times)

Step 1. Add the item to your cart

Step 2. Checkout or Click on the Chat button box that is at the bottom right of your screen

Step 3. Please tell us any info you think we would need to know

Step 4. Relax, our team is processing your request and an expert will be in touch to get you exactly what you need!

Product Description

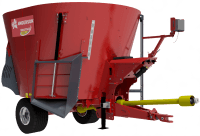

ANDERSON | Feed Mixer | A380 | Vertical Mixer | Single Auger (Right Side Trap Discharge)| 380-500 cu ft | Minimum 75 HP | For Tractor

DESCRIPTION

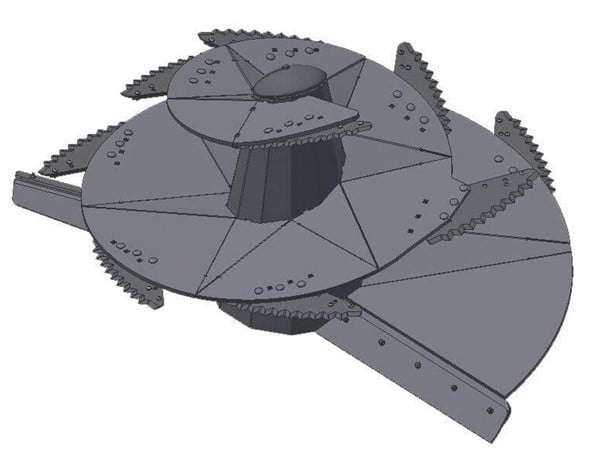

Designed to deliver unmatched efficiency in feed processing, the ANDERSON A380 Single Auger Vertical Mixer is a powerhouse tailored for high-output agricultural operations. Its compact, pull-type design makes it an excellent choice for farms where maneuverability and space efficiency are crucial. With a 380 cubic foot capacity (expandable to 500 cu ft), advanced TRI-CUT™ auger technology, and a durable build, the A380 ensures a faster, more consistent mix and discharge every time.

Whether you're working with dairy, beef, or mixed operations, the A380 offers the strength, precision, and intelligence required to meet today’s demanding feeding routines, while protecting your bottom line through reduced wear and improved material flow.

Key Features

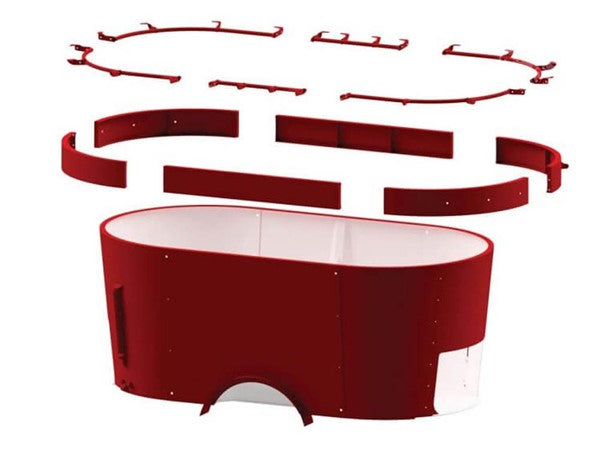

- Flexible Capacity: Base capacity of 380 cu ft, extendable up to 500 cu ft with optional extensions.

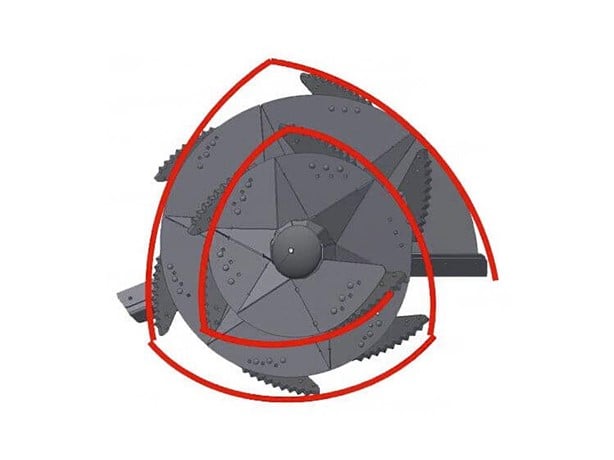

- TRI-CUT™ Auger System: Features adjustable, reversible knives and twin sweeping dispensers for up to 30% faster discharge.

- TRUE-CUT™ Hydraulic Restrictor Blades: A market-first innovation that helps avoid over-processing and maintains feed integrity.

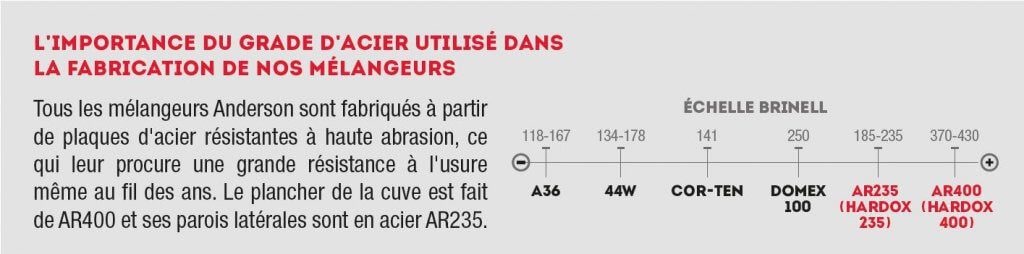

- Heavy-Duty Construction: Reinforced tub floor, AR235-grade steel walls, and shear bolt driveline security provide long-lasting durability.

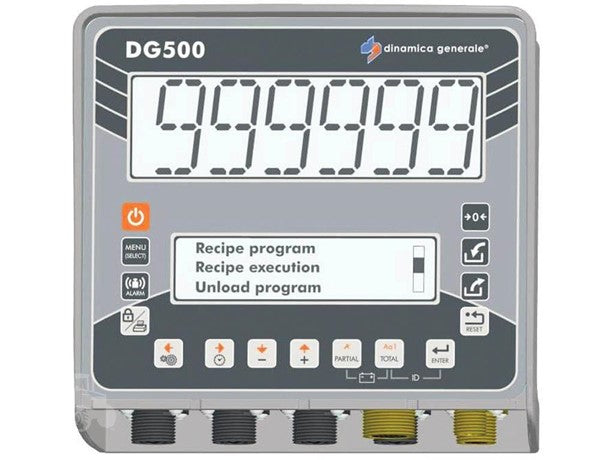

- Precision Weighing: Comes standard with the DG500 programmable indicator and 3-point scale system compatible with DTM suite.

- Optimized Material Flow: Rolled (not bent) sidewalls prevent material restriction, ensuring smooth auger performance.

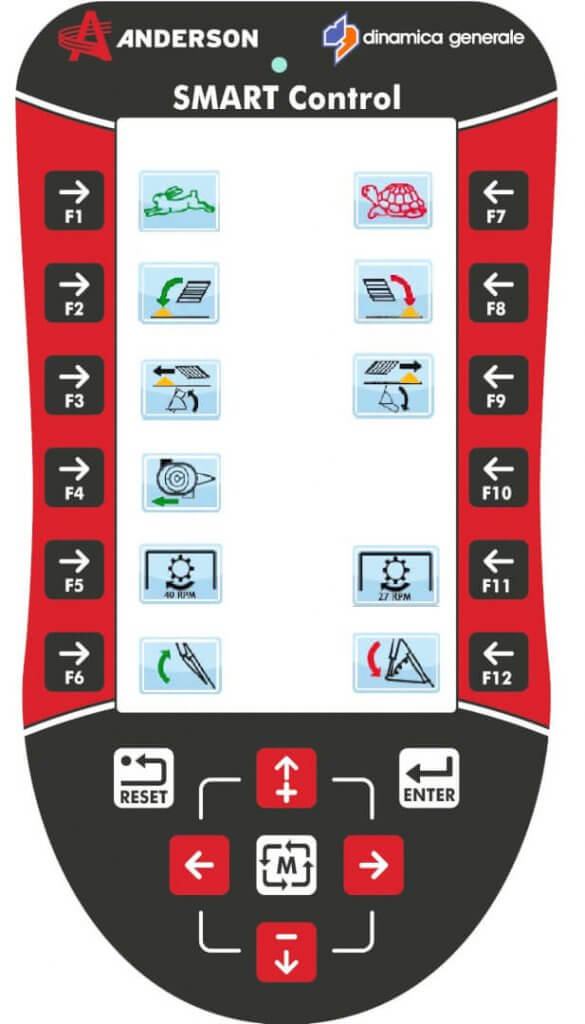

- Smart Controls (Optional): Optional SMART CONTROL remote lets you wirelessly manage recipes, speeds, and hydraulic functions.

- Discharge Options: Choose between right-side trap or optional front conveyor configurations.

- Low Horsepower Requirement: Efficiently operates with as little as 75 HP, reducing fuel consumption and operating costs.

Detailed Specifications

| Category | Details |

|---|---|

| Model | A380 (Right Side Trap Discharge) |

| Manufacturer | ANDERSON |

| Type | Vertical Mixer – Single Auger |

| Capacity (Base) | 380 ft³ (10.8 m³) |

| Capacity with 6" Extension | 420 ft³ (11.9 m³) |

| Capacity with 12" Extension | 460 ft³ (13 m³) |

| Capacity with 18" Extension | 500 ft³ (14.2 m³) |

| Number of Augers | 1 |

| Minimum PTO Horsepower | 75 HP (High Speed), 50 HP (Low Speed) |

| Auger RPM | 27 RPM (Low), 41 RPM (High) |

| PTO Shaft (Standard) | 540 RPM, 1" 3/8 Z6 |

| PTO Shaft (Optional) | 1000 RPM, 1" 3/8 Z21 |

| Gearbox (Optional) | 2-Speed D732, Ratio 1:1.5 |

| Floor Thickness | 3/4 in (AR235 Grade) |

| Sidewall Thickness | 1/4 in (AR235 Grade) |

| Flighting Thickness | 5/8 in (AR235 Grade) |

| Knives per Auger | 6 standard / 10 optional |

| Discharge Type | Right Side Trap (standard) |

| Discharge Options | Optional Front Conveyor |

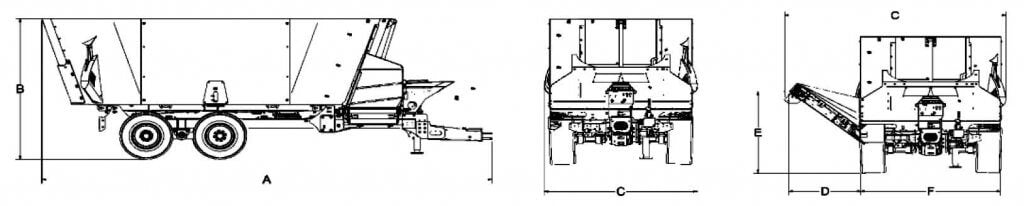

| Length | 217 in (5.51 m) |

| Height (no extension) | 106 in (2.69 m) |

| Height with Extensions | Up to 124 in (3.15 m) |

| Width (no conveyor) | 101 in (2.57 m) |

| Width (with conveyor) | 117 in (2.97 m) |

| Wheel Track Width | 86 in (2.18 m) |

| Hydraulic Flow Requirement | 10–15 GPM (37–56 L/min) |

| Hydraulic Pressure | 160–200 bar (2300–2900 psi) |

| Scale System | DG500 Digital Indicator |

| Load Cells | 3 |

| Empty Weight | 8465 lb (3839 kg) |

| Utility Load Capacity | 11,020 lb (4998 kg) |

| Axle Configuration | Single Axle |

| Tire Specification | 15.0/55-17 (26 PLY) |

Comparison Chart

| Feature | A280ST | S380ST | S280ST | S450ST | A380ST | A380FD | A450ST | A450FD |

|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

| Capacity (no extension) | 280 ft³ (7.9 m³) | 380 ft³ (10.8 m³) | 280 ft³ (7.9 m³) | 450 ft³ (12.8 m³) | 380 ft³ (10.8 m³) | 380 ft³ (10.8 m³) | 450 ft³ (12.8 m³) | 450 ft³ (12.8 m³) |

| Capacity (6" extension) | 316 ft³ (9 m³) | 420 ft³ (11.9 m³) | 316 ft³ (9 m³) | 500 ft³ (14.2 m³) | 420 ft³ (11.9 m³) | 420 ft³ (11.9 m³) | 500 ft³ (14.2 m³) | 500 ft³ (14.2 m³) |

| Capacity (12" extension) | 352 ft³ (10 m³) | 460 ft³ (13 m³) | 352 ft³ (10 m³) | 550 ft³ (15.6 m³) | 460 ft³ (13 m³) | 460 ft³ (13 m³) | 550 ft³ (15.6 m³) | 550 ft³ (15.6 m³) |

| Capacity (18" extension) | 388 ft³ (11 m³) | 500 ft³ (14.2 m³) | 388 ft³ (11 m³) | 600 ft³ (17 m³) | 500 ft³ (14.2 m³) | 500 ft³ (14.2 m³) | 600 ft³ (17 m³) | 600 ft³ (17 m³) |

| Number of Augers | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Length (A) | 176 in (4.46 m) | 154 in (3.91 m) | 140 in (3.56 m) | 154 in (3.92 m) | 189 in (4.79 m) | 217 in (5.51 m) | 190 in (4.84 m) | 219 in (5.57 m) |

| Height (B) no extension | 98 in (2.49 m) | 100 in (2.54 m) | 97 in (2.46 m) | 106 in (2.69 m) | 106 in (2.69 m) | 106 in (2.69 m) | 112 in (2.84 m) | 112 in (2.84 m) |

| Height (B) 6" extension | 104 in (2.64 m) | 106 in (2.69 m) | 103 in (2.62 m) | 112 in (2.84 m) | 112 in (2.84 m) | 112 in (2.84 m) | 118 in (3 m) | 118 in (3 m) |

| Height (B) 12" extension | 110 in (2.79 m) | 112 in (2.84 m) | 109 in (2.77 m) | 118 in (3 m) | 118 in (3 m) | 118 in (3 m) | 124 in (3.15 m) | 124 in (3.15 m) |

| Height (B) 18" extension | 116 in (2.95 m) | 118 in (3 m) | 115 in (2.92 m) | 124 in (3.15 m) | 124 in (3.15 m) | 124 in (3.15 m) | 130 in (3.3 m) | 130 in (3.3 m) |

| Width (C) without conveyor | 90 in (2.29 m) | 101 in (2.57 m) | 90 in (2.29 m) | 112 in (2.84 m) | 101 in (2.57 m) | 101 in (2.57 m) | 112 in (2.84 m) | 112 in (2.84 m) |

| Width (C) with conveyor (retracted) | 106 in (2.69 m) | 117 in (2.97 m) | 106 in (2.69 m) | 125 in (3.18 m) | 117 in (2.97 m) | 117 in (2.97 m) | 125 in (3.18 m) | 124 in (3.15 m) |

| Incline Conveyor Angle (degrees) | 26 @ 39 | 26 @ 39 | 26 @ 39 | 23 @ 39 | 26 @ 39 | 26 @ 39 | 26 @ 39 | 26 @ 39 |

| Outside Wheel Width | 86 in (2.18 m) | - | - | - | 86 in (2.18 m) | 86 in (2.18 m) | 86 in (2.18 m) | 86 in (2.18 m) |

| Discharge Point (3ft conveyor @ 26°) | 36-29 in | 30-34 in | 30-34 in | 29-33 in | 30-23 in | 30-28 in | 23-16 in | 23-21 in |

| Discharge Point (4ft conveyor @ 26°) | 36-40 in | 34-38 in | 34-38 in | 33-37 in | 41-45 in | 39-41 in | 40-44 in | 39-41 in |

| Discharge Point (5ft conveyor @ 26°) | 43-47 in | 41-45 in | 41-45 in | 39-43 in | 48-52 in | 46-48 in | 46-50 in | 46-48 in |

| Discharge Point (6ft conveyor @ 26°) | 47-51 in | 46-50 in | 45-49 in | 43-47 in | 53-57 in | 50-52 in | 50-54 in | 50-52 in |

| Discharge Point (7ft conveyor @ 26°) | 54-58 in | 53-57 in | 52-56 in | 49-53 in | 60-64 in | 57-59 in | 56-60 in | 57-59 in |

| Discharge Point (8ft conveyor @ 26°) | 59-63 in | 57-61 in | 57-61 in | 53-57 in | 64-68 in | 61-63 in | 60-64 in | 61-63 in |

| Discharge Point (3ft conveyor @ 40°) | 40-40 in | 40-40 in | 40-40 in | 40-40 in | 27-20 in | 28-25 in | 20-13 in | 21-18 in |

| Discharge Point (4ft conveyor @ 40°) | 47-47 in | 46-46 in | 46-46 in | 47-47 in | 52-52 in | 48-48 in | 53-53 in | 48-48 in |

| Discharge Point (5ft conveyor @ 40°) | 57-57 in | 57-57 in | 56-56 in | 57-57 in | 63-63 in | 59-59 in | 63-63 in | 59-59 in |

| Discharge Point (6ft conveyor @ 40°) | 64-64 in | 63-63 in | 63-63 in | 63-63 in | 69-69 in | 65-65 in | 69-69 in | 65-65 in |

| Discharge Point (7ft conveyor @ 40°) | 74-74 in | 73-73 in | 73-73 in | 73-73 in | 79-79 in | 75-75 in | 79-79 in | 75-75 in |

| Discharge Point (8ft conveyor @ 40°) | 80-80 in | 79-79 in | 79-79 in | 79-79 in | 85-85 in | 82-82 in | 85-85 in | 82-82 in |

| Discharge Height (3ft conveyor @ 26°) | 32-36 in | 30-34 in | 30-34 in | 33-37 in | 37-41 in | 35-37 in | 36-40 in | 35-37 in |

| Floor/Conveyor to Ground | 30 in (0.77 m) | 29 in (0.74 m) | 29 in (0.72 m) | 33 in (0.84 m) | 36 in (0.91 m) | 26 in (0.66 m) | 36 in (0.91 m) | 26 in (0.66 m) |

| PTO Shaft (Standard) | 540 RPM 1 3/8" Z6 | 540 RPM 1 3/8" Z6 | 540 RPM 1 3/8" Z6 | 540 RPM 1 3/8" Z6 | 540 RPM 1 3/8" Z6 | 540 RPM 1 3/8" Z6 | 540 RPM 1 3/8" Z6 | 540 RPM 1 3/8" Z6 |

| PTO Shaft (Optional) | - | - | - | 1000 RPM 1 3/8" Z21 | 1000 RPM 1 3/8" Z21 | 1000 RPM 1 3/8" Z21 | 1000 RPM 1 3/8" Z21 | 1000 RPM 1 3/8" Z21 |

| 2 Speed Gear Box | - | - | - | Optional | Optional | Optional | Optional | Optional |

| Min PTO HP (Low Speed) | - | - | - | 50 | 50 | 60 | 60 | |

| Min PTO HP (High Speed) | 60 | 40 | 30 | 50 | 75 | 75 | 85 | 85 |

| Auger RPM (Low Speed) | - | - | - | 27 RPM | 27 RPM | 27 RPM | 27 RPM | |

| Auger RPM (High Speed) | 41 RPM | 17 RPM | 17 RPM | 17 RPM | 41 RPM | 41 RPM | 41 RPM | 41 RPM |

| Standard Planetary Ratio | 1602 @ 13.4 | 1603 @ 25.89 | 1603 @ 25.89 | 1603 @ 25.89 | 1602 @ 13.4 | 1602 @ 13.4 | 1602 @ 13.4 | 1602 @ 13.4 |

| Floor Thickness | 5/8 in | 3/4 in | 5/8 in | 3/4 in | 3/4 in | 3/4 in | 3/4 in | 3/4 in |

| Sidewall Thickness | 1/4 in | 1/4 in | 1/4 in | 1/4 in | 1/4 in | 1/4 in | 1/4 in | 1/4 in |

| Flighting Thickness | 5/8 in | 5/8 in | 5/8 in | 5/8 in | 5/8 in | 5/8 in | 5/8 in | 5/8 in |

| Standard Knives per Auger | 6 / 10 optional | 6 / 10 optional | 6 / 10 optional | 8 / 12 optional | 6 / 10 optional | 6 / 10 optional | 8 / 12 optional | 8 / 12 optional |

| Driveline Security | Shear bolt | Shear bolt | Shear bolt | Shear bolt | Shear bolt | Shear bolt | Shear bolt | Shear bolt |

| Hydraulic Flow Requirement | 10-15 US gal/min | - | - | - | 10-15 US gal/min | 10-15 US gal/min | 10-15 US gal/min | 10-15 US gal/min |

| Hydraulic Pressure | 160-200 bar | - | - | - | 160-200 bar | 160-200 bar | 160-200 bar | 160-200 bar |

| Load Cell | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

Manuals & Documents

PRODUCT MANUAL

PRODUCT BROCHURE

General Warranty Info:

- Ripping It Outdoors works closely with our manufacturers to supply and support your products warranty needs as best as possible!

- The majority of products come with a manufacturer represented warranty against manufacturing defects for at least a 12 month period after the date of sale.

- Expendable components and "wear parts" including but not limited to blades, knives, teeth, oil, chain sprockets, skid shoes, knife mounting discs, and similar components are usually excluded from manufacturer warranties.

- Please reach out to us for any specific warranty information neededabout products and parts you can’t find!

Videos

Shipping

$1 Shipping Quote Info:

- Contact Us For Shipping Quotes. All $1 products are listed as quote only because we can not display their pricing online.

- Low shipping rates for customers. We have negotiated the best possible rates for customers from our trusted carriers (ODFL, ESTES, UPS, and FedEx) & Top Private Drivers

- Negotiate shipping rates if you think we can do better please reach out. Keep in mind some shipping rates also include assembly & configuration as well!

- Complimentary lift gate service on all freight shipments where it’s possible. We guarantee safe delivery!